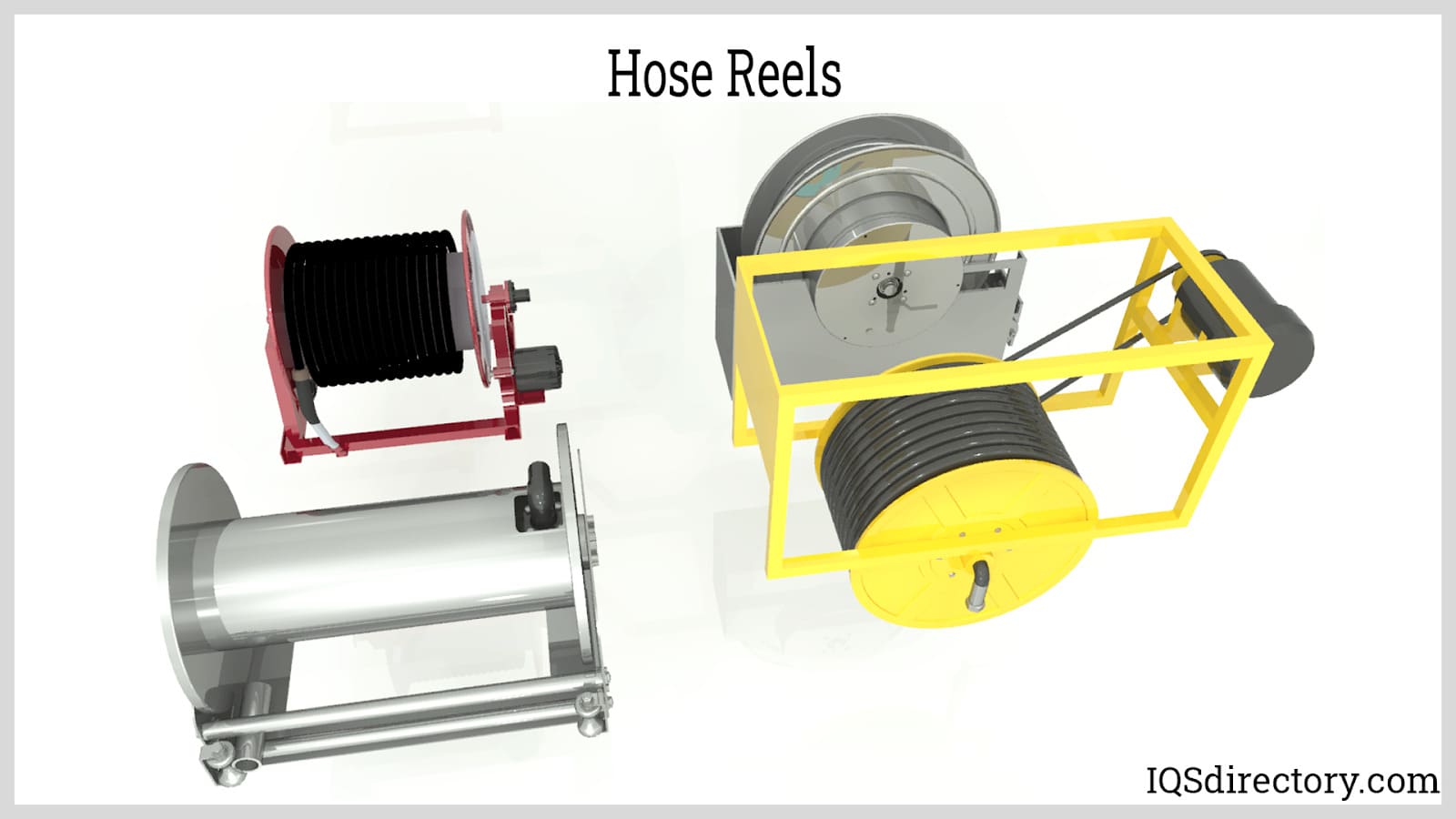

Hose Reels

When it comes to essential tools and gadgets in a workshop, the hose reel often goes unnoticed. However, its impact on functionality and organization makes it a crucial piece of equipment. This article aims to provide an in-depth look at hose and cord reels, focusing on their design and industrial uses.

At its core, a hose reel is a cylindrical device designed to store hoses and other lengthy materials. Its structure simplifies the winding and unwinding process, ensuring tangle- and kink-free storage. Hose reels are available in various materials, with plastic, fiberglass, and metal being the most common. They come in different sizes to accommodate a wide range of needs, from a simple garden hose to a heavy duty industrial fire hose. Some reels are also designed to hold large amounts of rope and cable, and even provide a connection for electric currents.

Hose and cord reels are commonly found in commercial and professional settings, especially in industries like manufacturing and construction. However, they are also used in less obvious places. For example, hospitals and emergency vehicles use hose reels to extend equipment and tools for greater mobility. Car mechanics use them to store vehicle exhaust hoses, while farmers and agriculturists rely on large industrial reels for crop irrigation. Food packaging companies also benefit from hose reels to clean large areas and sanitize equipment and trash collection zones.

Hose reels are built to meet the specific requirements of various applications. For residential use, smaller hose reels are available to store lighter hoses, such as a typical garden hose. For larger hoses, like those used by fire departments or in construction, reels are constructed from more durable materials and larger sizes to support the extra weight and length. In industrial manufacturing settings, hose reels are used for winding hoses as well as cables for arc and gas welding, air and hydraulic tools, industrial lighting, and more. Some hose reels are dedicated solely to transportation, while others serve both storage and transportation purposes. There are also reels that allow the hose to be used while it is still wound, and retractable hose reels that enable automatic, self-contained retrieval of the unwound hose.

Across all these different types of hose reels, the key benefit is the ease of access and efficient storage, which is why they are so popular with consumers.

The History of Hose Reels

The concept of the hose reel dates back to 17th-century Holland, where inventors were working on improving the fire hose. After much experimentation, they created a design that proved both functional and effective, though the hoses it produced were heavy. To address this, specialized drums were used to transport the hoses. Over time, the design of these drums evolved, and hose reels eventually emerged as a more practical, built-in solution for fire trucks. As ideas and technologies spread, the hose reel quickly became a universally adopted tool.

With the onset of the Industrial Revolution in the 18th century, new materials and machinery became available, which helped reduce the weight of the fire hose. Consequently, the design of the fire hose reel also evolved. The familiar spool shape became the standard, offering better storage while still supporting the weight of the hoses. As the design of hose and cable reels became more widespread, their versatility became increasingly evident. With rapid technological advancements, hose reels were mass-produced, and while the size, materials, and design varied based on specific needs, the core concept and function of the hose reel remained consistent.

Benefits and Advantages of Hose Reels

Hose reels offer significant benefits in maintaining an organized and efficient workplace. By keeping hoses and cables neatly wound and off the floor, they reduce the risk of accidents and tripping, making work environments safer. Their design ensures that the weight of the hoses is evenly distributed, preventing tangling and kinking, which also helps reduce wear and tear that can occur from storing hoses and cables haphazardly on the floor or in a disorganized pile.

These reels are highly portable; they can be easily mounted on a wall in smaller work areas or placed on a reel cart for quick mobility. Their sleek design allows them to blend seamlessly into any workspace while occupying minimal space. With their versatile applications, hose reels can be tailored to meet specific needs, holding various items, and offering options such as automatic or spring-based mechanisms to suit different preferences.

Additionally, hose reels reduce the likelihood of theft. By securing hoses and cables on the reel, it becomes more difficult for them to be stolen compared to when they are left out in the open. Overall, hose reels improve workplace efficiency, eliminating the need to search for scattered hoses or cables. With everything neatly stored in one place, workers can quickly access and use the equipment, saving time and reducing frustration.

Design of Reels

Designing Hose Reels

As previously mentioned, the original designs for hose reels were large metal drums or rods of uniform width. However, as hoses and cables became lighter and consumer demands grew, the design of the reel evolved. The initial bulky setup was streamlined and transformed into the familiar large spool shape we see today.

At its core, a hose or cord reel is designed to wrap its contents around a sturdy core, much like thread is wrapped around a spool. The design features a narrower center with two larger barriers on either end, which helps keep the contents secure, organized, and easily accessible. The specific details of a reel can vary based on the consumer's needs. For example, some hose reels feature a spring-driven mechanism for self-retraction, while others use a manual hand crank or motor to retract the contents.

Hose Reel Materials

The materials used in the construction of hose reels are crucial. For basic uses, such as a garden hose or an extension cord, a simple plastic body may suffice and is both affordable and functional. However, for longer hoses or more industrial applications, manufacturers must ensure the reel can support the weight of the industrial hose and endure the conditions it will be exposed to. For reels used in harsh outdoor environments, weather-resistant materials and anti-corrosion metals are required. Fiberglass and stainless steel are popular choices due to their durability, resistance to scratches, and ability to withstand extreme temperature changes and moisture.

Specific applications may require particular materials; for example, medical cord reels are often made from sanitary-grade materials, such as 304L stainless steel, while industrial reels typically use heavy-duty metals like stainless steel, steel, or aluminum for their corrosion resistance and strength.

Customizing Hose Reels

Customization of hose and cable reels is ideal for those seeking a personalized solution for their home workspace. If building a reel by hand, the material choices are virtually limitless, as long as the materials can withstand the weight and usage demands. Customization options include swapping out handles or cranks, engraving the surface, or painting the reel to match personal preferences or workspace aesthetics.

Hose Reel Images, Diagrams and Visual Concepts

Hose reels mechanisms for the storing and use of a hose on a barrel designed to make hoses, cords, flexible tubing, or wire available for usage.

Air hose reel are connected to an air compressor with the hose wound around the reel and to prevent extra wear on the hose they are hung from the ceiling.

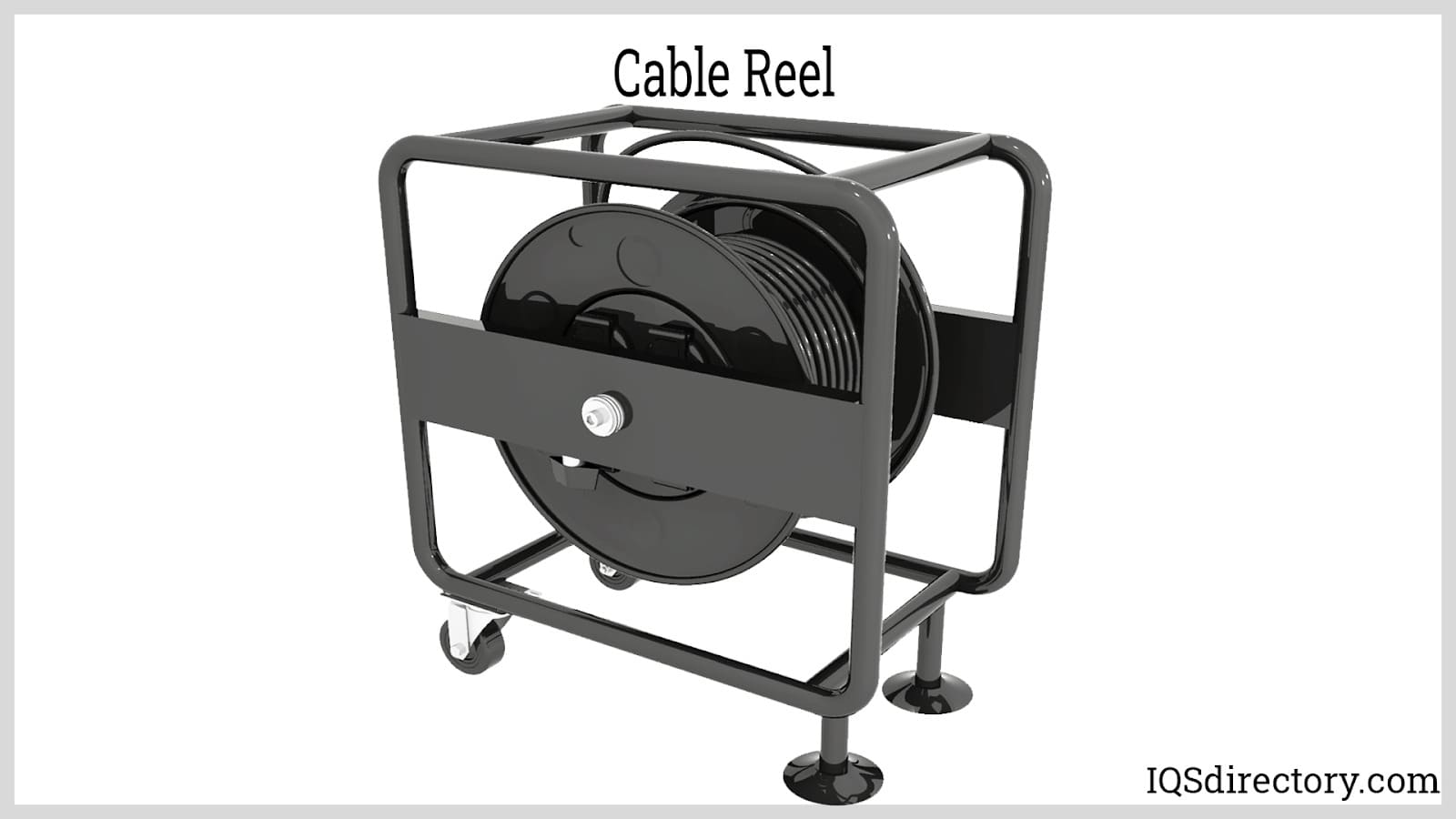

Cable reels hold conductive cable or lifting cable, either for storage, unwinding, and winding.

Cord reels hold extension cords used for supply power to electrical equipment or devices.

High pressure hose reels prevent the hoses from kinking, tangling, or being damaged, which could lower the pressure of the hose line.

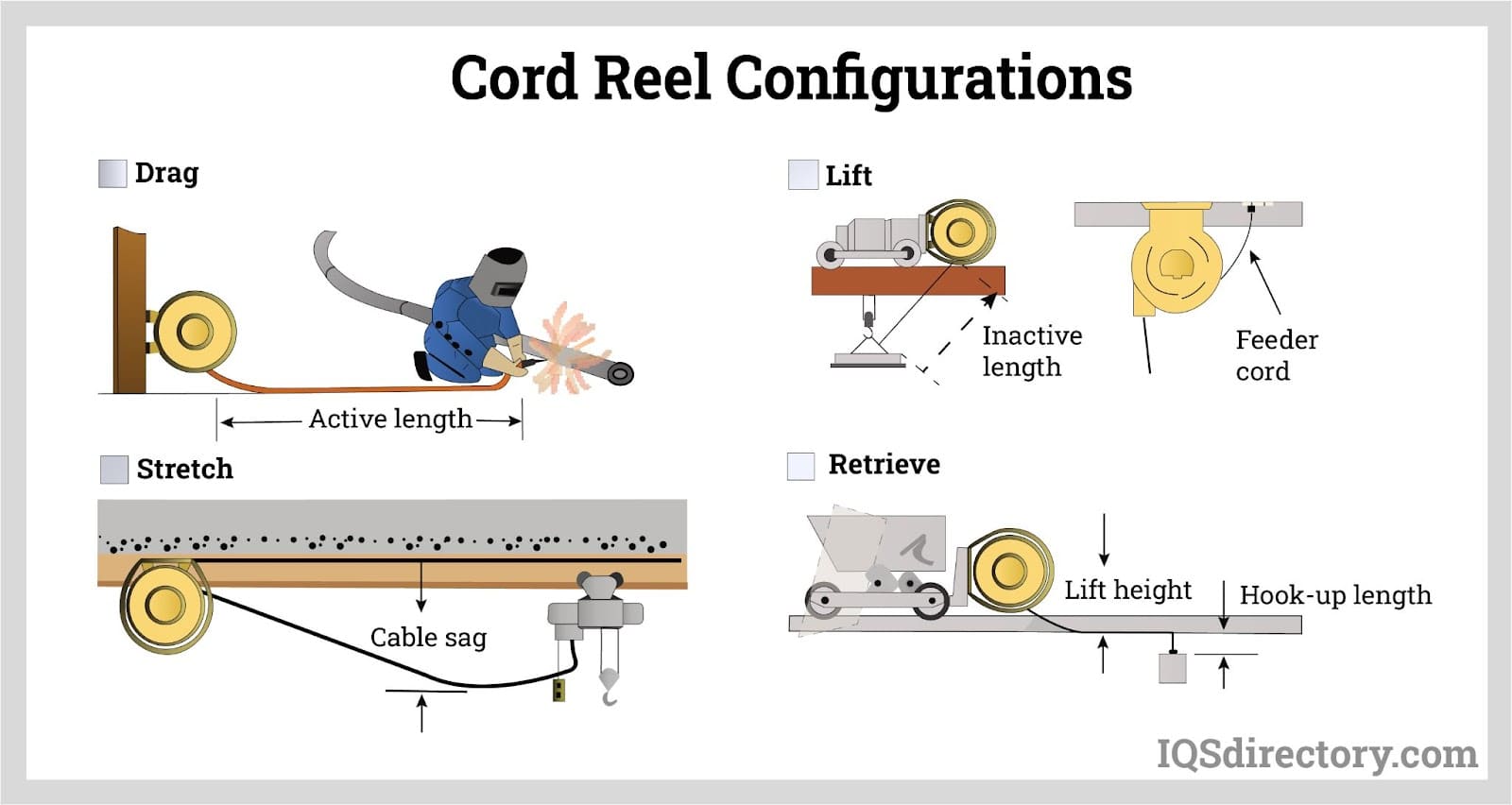

Installation arrangements of cord reels depending on their usage based on there lift, drag, stretch, retrieve, and vertical pick up.

Hose Reel Types

Air Hose Reels

Designed specifically to store air hoses, typically of small diameter, these compact reels are ideal for keeping air hoses organized and easily accessible.

Automatic Hose Reels

These reels automatically retrieve the hose using either batteries, electricity, or water/air pressure, offering convenience and ease of use.

Cable Carriers

Made up of a series of flexible links, cable carriers are used to organize and house conduits such as cables, hoses, and chains, providing a streamlined solution for their management.

Cable Reels

These reels are built to store cables for electrical or industrial purposes. They consist of several linked parts designed to hold and organize materials like cables, ropes, chains, and hoses.

Cord Reels

Cord reels are used to store, extend, and automatically rewind electrical cables, often used to power mobile machinery from a stationary source.

Electric Reels

Utilizing electric power to wind and unwind hoses, electric reels are ideal for situations where heavy hoses need to be relocated frequently, such as in airplane refueling applications.

Extension Reels

A cylindrical device designed to keep electrical cords organized, extension reels are often used to supply power to tools in environments where equipment is constantly being moved.

Fire Hose Reels

These reels provide easy access to a water supply for fire protection, offering a more substantial alternative to fire extinguishers. They are commonly found in high-risk areas like large schools, warehouses, and factories.

High Pressure Hose Reels

Built to handle pressurized hoses, high-pressure hose reels are used in industrial processes and manufacturing operations to store and manage pressurized air and water hoses.

Industrial Reels

These reels are used in applications requiring high product flow or longer hose lengths, making them ideal for industrial settings.

Medical Cord Reels

Used in medical environments, these reels store and rewind conductive cords or lifting cords that power mobile medical equipment like crash carts through connection to a stationary power source.

Phone Cord Reels

Self-retracting reels designed for telephone cords, allowing for easy storage in small, portable containers.

Retractable Hose Reels

Equipped with cranks, these reels allow for easy retraction and storage of hoses, keeping them neatly organized and easily accessible.

Spring Reels

Driven by a spring mechanism, these reels are suitable for various applications in industries such as agriculture, commercial use, and greenhouses.

Static Discharge Reels

Used to ground equipment in hazardous environments, these reels prevent static electrical buildup, reducing the risk of sparking and potential explosions.

Truck Mounted Reels

These reels are designed for attachment to trucks or vans, with various types including air hose reels, static grounding reels, and water hose reels, commonly used in service trucks and mechanics' trucks.

Water Hose Reels

Cylindrical cranks designed to wind water hoses manually or mechanically, keeping them organized and ready for use.

Welding Reels

Welding reels facilitate smooth operation during welding by providing easy access to welding cables, often engineered from durable materials and hard-coated for increased longevity.

Reel Features

The primary and most valuable feature of a hose reel is its mobility. While many hose reels can be mounted securely on the wall, there are situations where it is more convenient to allow the reel to move freely. Reels can be suspended from the ceiling to provide access from various angles, and in industrial settings, they can be mounted on carts or vehicles for easy transportation and increased versatility.

Installation and Product Care for Hose Reels

When using a mounted hose reel, it’s crucial to follow the manufacturer’s instructions to ensure it is securely attached to the wall. The instruction manual typically specifies the appropriate nails or screws required for mounting. Avoid using tape or glue, even for lightweight reels, as this could result in the reel falling, potentially causing injury or damage to equipment. For portable hose reels, make sure they are securely positioned on their cart or wagon, with the weight evenly distributed to prevent tipping. If the reel is made of materials prone to rust or corrosion, store it in a dry, cool location indoors to protect its integrity.

Proper storage and care are essential to maintaining the functionality and longevity of your hose reel. When using a hand crank, always wind the hose fully back into place. Leaving the hose on the ground defeats the purpose of the reel and can pose a tripping hazard. For spring reels, ensure you pull the cord with a firm, controlled motion, and lock it securely when the desired amount is gathered. Avoid swinging the cord around while attached to the reel, and don’t pull too forcefully, as this can damage the cord or cause it to detach from the reel.

Automatic reels should never be left unattended. Ensure the hose or cord is laid out untangled before winding to aid the process. If the reel has advanced settings, check them for accuracy before use. When not in use, store the reel in its designated area or move it out of the way to avoid obstructing workplace traffic.

What to Consider When Choosing a Hose Reel

Before purchasing a hose reel, it’s essential to consider various aspects of the application. One key factor is the type of medium the hose will carry. For air, especially in pneumatic tools, determining the required pounds per square inch (psi) that the hose must handle is crucial. Similarly, hoses used for conveying oil, grease, or lubricants also require knowing the specific psi range they need to withstand. For applications that demand more torque, the inner diameter (ID) of the hose is important, as higher torque applications typically need hoses with a larger ID. For cord reels, it's necessary to consider the type of cable, the length, the number of conductors, and the wire size.

Besides selecting the wrong hose reel for the application, there are other reasons why hose reels might fail. For example, if a spring hose reel is not properly sealed and exposed to the atmosphere, the internal spring can rust and eventually break. In addition, using the wrong materials for parts—like thin sheet metal or cast aluminum for latching mechanisms—can lead to failure.

It’s important not to confuse a good manufacturer with the right manufacturer. While a good manufacturer may have high ratings and positive reviews, this doesn’t guarantee the product will meet specific needs. If possible, inspect the equipment in person to ensure it fits your exact requirements before making a purchase.

Hose Reel Terms

Ball Stop

Also known as a "hose" or "bumper" stop, this component is used to control the retraction length. Ball stops are frequently required when accessories like drills and air guns are installed on hose reels.

Bracket

A simple L-shaped component, with one arm fixed to a vertical surface such as a wall, while the other arm extends horizontally to support the hose reel.

Bridge

A device placed over a section of hose to allow traffic to pass over it without causing damage to the hose.

Carcass

The fabric, cord, and/or metal reinforcing section of a hose, which is distinct from the tube or cover.

Core Diameter

The diameter of the inside of the reel.

Coupling

A fitting attached to the end of a hose to connect two hose lines together or to link the hose to appliances, nozzles, discharge valves, fire hydrants, etc.

Cover

The outermost part of the hose that protects the hose reinforcement from physical and environmental damage.

Fairlead

A square hose guide that helps direct the hose.

Guide Arm

A piece that typically extends from the side of the hose reel. Its purpose is to guide the hose in a straight line, helping prevent tangling and making hose retrieval easier.

Lift Height

The vertical distance measured from where the hose is positioned to the centerline of the spool.

Pivot Base

A base that allows the hose reel to turn in multiple directions.

Pressure Rating

The maximum pressure capacity of a hose or cord. For air and water hoses, it is measured in pounds per square inch (psi), and for electrical cables and power cords, it is measured in voltage (V).

Ratchet

A mechanism that holds the hose reel spools in place at specific points during payout.

Reel Capacity

The maximum length of hose that a reel can efficiently store, usually expressed in feet.

Reinforcement

The central component of a hose that provides its strength. The hose's working pressure depends on the type and amount of reinforcement used in its construction.

Safety Wrap

The portion of the hose that remains on the reel when the rest has been completely unwound.

Slip Rings

A device that maintains an electrical connection between a stationary structure and a rotating structure, used in systems that require power/data transmission while allowing rotation.

Spool Axial

The device around which the hose or wiring is wound. It rotates with the swivel to load and unload the hose.

Swivel

A supported pivot that allows the hose reel to rotate in a horizontal plane, facilitating the winding and unwinding motions. The swivel also transfers gas or fluid from a fixed source to a rotating source.

Tie Rod

A component that ensures the spool flanges are securely attached to the drum, maintaining their rigidity.

More Hose Reels